How to Minimize Tire Wear in Your Fleet with TPMS

Table Of Contents

Introduction

Incorrect tire pressure is one of the most common—and simultaneously most underestimated—causes of increased operating costs and unplanned vehicle breakdowns. Especially in trucks and transport vehicles, tire pressure directly impacts road safety, operating costs, and your company’s environmental footprint.

Significantly lower-than-recommended tire pressure can lead to excessive tire heat buildup, accelerated wear, and, in the worst case, tire blowouts. This poses not only an acute danger to drivers and other road users but also incurs significant costs due to vehicle downtime and unexpected repairs.

In everyday operations, it is often the small pressure deviations of just 0.2 to 0.5 bar that add up over time and develop into a creeping problem. Many fleet managers still rely on visual checks or occasional manual measurements, which, given today’s technical capabilities, is outdated and carries considerable risk.

To help you avoid unnecessary downtime, high consequential costs, and other problems in your fleet, this blog provides comprehensive information about tire monitoring systems and tire management for your fleet.

The Cost of Incorrect Tire Pressure

At first glance, tire pressure seems to have little influence on vehicle status. However, it directly affects several cost factors within a fleet:

Increased Tire Wear: Low pressure enlarges the tire’s contact patch, causing more deformation in the sidewalls. This results in excessive heat buildup, faster abrasion, and uneven wear.

Increased Fuel Consumption: A larger rolling resistance surface requires more energy to move the tires. This means higher fuel consumption and increased CO₂ emissions. Studies show that even a 0.5 bar pressure deficit can increase fuel consumption by up to 5%—a significant cost factor for larger fleets!

Unnecessary Repairs: Over time, incorrect tire pressure can cause collateral damage to the suspension, chassis, and rims. These damages often go unnoticed until major repairs are needed.

Additional indirect costs include unplanned workshop visits, missed delivery deadlines, or the need for replacement vehicles. Especially in times of supply chain bottlenecks and rising operating costs, any unexpected breakdown can significantly affect your business results.

Helpful Tips for Tire Pressure:

When is higher tire pressure necessary?

During heavy loading or extended highway driving, as the vehicle weight compresses the tires

In high outdoor temperatures, as rubber expands and pressure drops

An intelligent TPMS system can automatically provide recommendations or warnings when optimal pressure levels are exceeded.

When is lower tire pressure necessary?

In rough terrain driving, slightly reduced pressure can improve traction

In wintry conditions, a marginally lower pressure (within manufacturer limits) increases contact area and grip

In very cold weather, as cold air takes up less volume and reduces pressure

How Does Tire Wear Affect Vehicles?

In cases of incorrect tire pressure, increased tire wear is often the first—and most significant—issue. “Tire wear” refers to the gradual degradation of the tire material, especially the tread, caused by friction, loads, temperature effects, and road conditions.

Every rotation of the tire applies forces to the rubber, leading to abrasion. This effect is even more pronounced in commercial vehicles like trucks, vans, or buses, due to their heavy loads, long distances, and demanding operating conditions.

We distinguish between normal, even wear and uneven or premature wear. The latter typically indicates technical problems or incorrect settings—such as too low or too high pressure, incorrect axle geometry, or improper loading.

Severe or uneven wear can lead to serious consequences:

Reduced Driving Safety: Decreased traction, longer braking distances, increased aquaplaning risk

Higher Fuel Consumption: Uneven tires increase rolling resistance

Shorter Tire Lifespan: More frequent replacements = higher costs

How to Detect Incorrect Tire Pressure and Emerging Wear?

For smooth and safe vehicle operation, tire pressure should always be monitored. Even minimal deviations can lead to increased wear and affect handling:

How does low pressure affect performance?

Increased flexing and heat generation in the tire

Uneven wear, especially on the tire shoulders

Higher rolling resistance and fuel consumption

Poor steering response and longer braking distances

Higher risk of tire damage and sudden pressure loss

How does high pressure affect performance?

Smaller contact patch causes faster center tread wear

Reduced ride comfort due to harder rolling

Less traction on wet roads, greater aquaplaning risk

Increased sensitivity to road damage and potholes

Extreme overinflation: risk of blowouts over bumps

Incorrect tire pressure often only becomes apparent when it’s too late—but there are clear signs to watch for in fleet operations:

Common signs of incorrect tire pressure:

Unusual Tire Wear:

Center tread wear = usually too much pressure

Shoulder wear = often too little pressure

Unstable Handling:

The vehicle sways more or reacts sluggishly to steering

Longer Braking Distances:

Especially on wet or inconsistent road surfaces

Increased Fuel Consumption:

Fuel tank empties faster than usual without changes in driving behavior

Frequent Tire Failures or Breakdowns:

More frequent pressure losses, blowouts, or cracks

Uneven Tread Depth on the Same Axle:

Tires on the same axle should wear evenly. Major differences indicate misalignment or incorrect pressure.

How can you limit tyre wear in your fleet? Installing tyre pressure monitoring systems (TPMS) is an effective solution. These systems provide automated, continuous monitoring of tyre pressure. Integrated with your fleet management tools, they also collect valuable data on the condition of vehicles and enable you to act quickly in the event of any anomalies.

What is a TPMS and Why is it Important?

The Tire Pressure Monitoring System (TPMS) is an electronic system that monitors tire air pressure. It comes in two main types:

Indirect TPMS: Doesn’t measure pressure directly, but infers it from wheel speeds and ABS data. These are low-cost but less accurate and prone to false alarms. Slow pressure loss is often detected too late.

Direct TPMS: Uses pressure sensors inside the tires to measure both pressure and temperature. These values are transmitted via radio to the control unit. Tire pressure sensors are now standard equipment in modern fleets.

For commercial fleets, direct systems are clearly superior. They provide real-time, highly accurate data and integrate easily into digital systems. Every fleet manager should ask: Is our tire pressure monitoring system up to date, and are we using the data to its full potential?

How to Reduce Tire Wear

Tire wear is one of the largest cost factors in fleet management. Here are a few key strategies to reduce it:

Continuous Pressure Monitoring: The most effective method. Ideally, check pressure every two weeks or before long trips. Modern fleets can use automated systems like TPMS for real-time alerts.

Regular Wheel Alignment: Misalignment causes uneven wear. Always check alignment after accidents or major impacts

Tire Rotation: Regularly rotating tires ensures even wear. Rotation patterns vary by vehicle type and drivetrain – check manufacturer guidelines.

Optimize Load Distribution: Overloading and uneven weight distribution accelerate wear. Ensure vehicles are not overloaded and loads are balanced.

Avoid Incorrect Pressure: As discussed, proper pressure extends tire life. Too low = heat buildup; too high = center wear.

Seasonal Adjustments: Adjust pressure for seasonal temperature swings. Rule of thumb: pressure changes ~0.1 bar per 10°C difference.

Systematic Maintenance and Inspection: Implement a structured (predicitve) maintenance plan that includes inspections of tread depth, wear patterns, and tire age.

Despite these manual steps, the biggest challenge is continuous monitoring of large fleets. Solutions like Echoes’ CarFleet use intelligent networking and data analytics to enable predictive, automated monitoring.

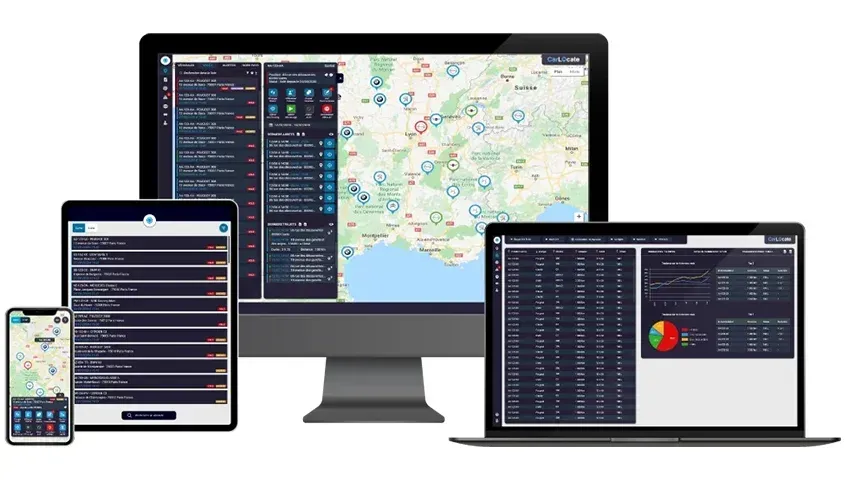

CarFleet - The Integrated Tire Pressure Solution

CarFleet by Echoes makes tire pressure control part of a comprehensive fleet management solution. The software continuously analyzes all key vehicle parameters, including tire pressure, in the context of:

Engine condition and oil temperature

Mileage and driving duration

Location and geofencing zones

Incident reports and maintenance schedules

Driving behavior and eco-driving data

CarFleet detects slow air losses before they become critical. Combined alerts notify you of risks in advance. Fleet managers can take immediate action, such as scheduling/ predicting maintenance or rerouting the vehicle.

CarFleet’s key feature is brand-independent integration of all vehicle data into one platform. Real-time data is collected directly from OEM systems – no extra hardware or manual input required. This sets it apart from traditional systems that rely on additional sensors or manual data entry.

CarFleet Features

For fleet operators, the advantages and use cases are numerous:

Real-time monitoring of all vehicles via a central platform

Proactive maintenance based on actual needs, not fixed intervals

Seamless integration with existing processes and systems

Immediate alerts for pressure loss, tire damage, or compound risks

Automatic detection of when to check tire pressure

Predictive failure forecasting

Tire Pressure Monitoring Saves Real Money

Tire pressure is no longer a minor issue. It affects the efficiency, safety, and sustainability of your entire fleet. With the right technology, it becomes a real lever for efficiency, saving you money and increasing safety.

Modern TPMS sensors combined with smart software like CarFleet offer significant advantages:

Early detection of pressure loss before it becomes critical

Extended tire life through optimal pressure and timely maintenance

Reduced fuel costs through lower rolling resistance

Increased safety through better driving stability

Lower CO₂ emissions through more efficient operation

Echoes utilizes connected vehicle data directly from manufacturers, regardless of make or model. This data is converted into a universal format, allowing you to tap into the hidden value of your fleet data within minutes – the perfect foundation for a modern TPMS Tire Pressure Monitoring System.

The question of when to check tire pressure is answered automatically by modern systems – continuously and in real time. Scheduled maintenance intervals are replaced with data-driven predictive interventions. This way, you can sustainably minimize tire wear in your fleet while maximizing operational safety.

Disclaimer: The tips, times, or penalties provided here have been carefully compiled to the best of our knowledge. No guarantee of completeness or exclusivity of the content is provided. The information does not replace legal advice or information from authorities. It is non-binding. No guarantee is given that the information can be used as evidence in case of disputes.